Dependable High-Output Pre-Roll Machines for Cannabis & CBD Manufacturers.

No Fluff. No Gimmicks.

513 Packed & Closed Prerolls in Minutes!

Adaptable. Reliable. Scalable.

Pro-Grade Pre-Roll Machines are redefined with the FLEXPAK MAX.

An ultra dependable, cone-filling workhorse that efficiently produces 513 precision packed & closed pre-roll cones at a time.

Built by Operators, for Operators.

When we got into the industry five years ago, we burned through hundreds of thousands of dollars on machines that just didn’t work. In a last-ditch effort to save our business, we rolled up our sleeves and built the FlexPak Max Machine ourselves. Fast forward to today—what saved our business is now helping companies around the world crank out more pre-rolls and make more money.

The FlexPak Max is the only pre-roll machine designed by real operators for real operators—battle-tested, no fluff. Our mission was simple: build something that outlasts, outperforms, and outsmarts every challenge in cone production.

Our thoughts behind the machine:

Outlast

Set out to eliminate the frustration of cheap, prone to break machines.

Use high-grade, locally sourced materials to ensure durability and avoid supply chain delays.

Commit to building every machine in-house in our Oklahoma facility for complete quality control.

Outperform

Aim to solve slow, inconsistent, low quality output common in other machines.

Design every detail for speed, reliability, and precision.

Focus on maximizing efficiency while reducing waste and downtime.

Outsmart

Remove the complexity and learning curve from pre-roll production.

Build a system to be tool-free, intuitive, and easy for anyone to use.

Design with simplicity in mind to streamline workflows and reduce operator error.

The Result?

The Ultimate Preroll Machine, Combined with a Battle-Tested Assembly Line Workflow.

Built to Crush!

Pre-Roll Manufacturing

is Broken

Are You Facing These Challenges?

Constant breakdowns and endless tweaks? They’re killing your output and draining your profits.

The FlexPak Max runs with just 30 minutes of downtime a month — compared to 8+ hours a week on average from the other guys. Pair it with our battle-tested workflow, and you’ll spend more time rolling and less time wrenching.

Over staffed and labor-heavy closing processes are bottlenecking your growth.

Labor costs crushing margins? The FlexPak Max slashes manual work with precision crowning tools, reducing the need for a bloated staff that cuts closing labor by 50% or more — keeping your line lean and fast.

Inconsistent weights and extra touchpoints are wrecking your efficiency.

Our proprietary Flex Metering tech adjusts in real-time for material, density, and humidity — delivering consistent weights, every time that will keep your line flowing. Less touches = more profit.

Scaling feels impossible without massive reinvestment.

The FlexPak Max Pumps Out 5,000 to 24,624+ Cones/Day—No Major Upgrades, Just Pure Efficiency. Drop in a Second Machine and Dominate with 49,248+ Daily. Max ROI. Minimal Downtime. Built to Lead.

Unreliable machines, wasted investment, profit dips, growth plateaus?

This is exactly why we built the FlexPak Max. Have questions?

Book a pre-demo call & personalized consult today!

FlexPak Max

Built for Performance. Designed for Efficiency.

"The FlexPak Max makes the difference. Zero down time for our crew. Reduced labor costs by 38% while increasing output by 42%"

- G&S Distribution

Real Results, Real Growth

We're proud to partner with a growing network of preroll companies, delivering dependable high-output pre-roll machines for cannabis & CBD Manufacturers. Ultimately driving significant improvements in their operations and profitability across the US and Canada.

Join operators who’ve 10X’d production in months using our field-tested process.

Need 5,000 Pre-Rolls a Month? No Problem.

Need 2 Million a Month?

Sure, We’ve Got a Client Doing That Right Now!

Need 5,000 Pre-Rolls a Month? No Problem.

Need 2 Million a Month?

Sure, We’ve Got a Client Doing That Right Now!

FlexPak max reviews

Don't Take Our Word For It.

See What Clients Are Saying

"The backup, became the solution"

"As a backup, we bought a FlexPak Max just to keep production moving. But here’s the twist: it worked so well, we bought another… then another." - Jim R.

"This thing is a beast."

"No more babysitting the machine, no more uneven packs. The crowning tool alone saves us hours, and the consistency? Unmatched." - Trevor B.

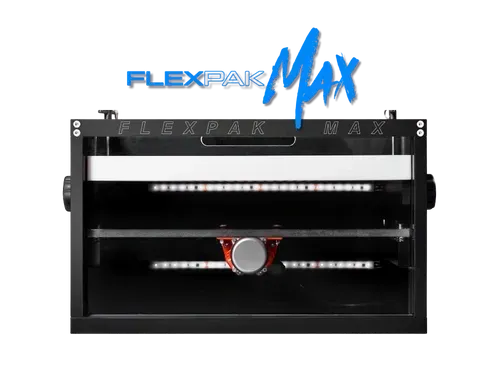

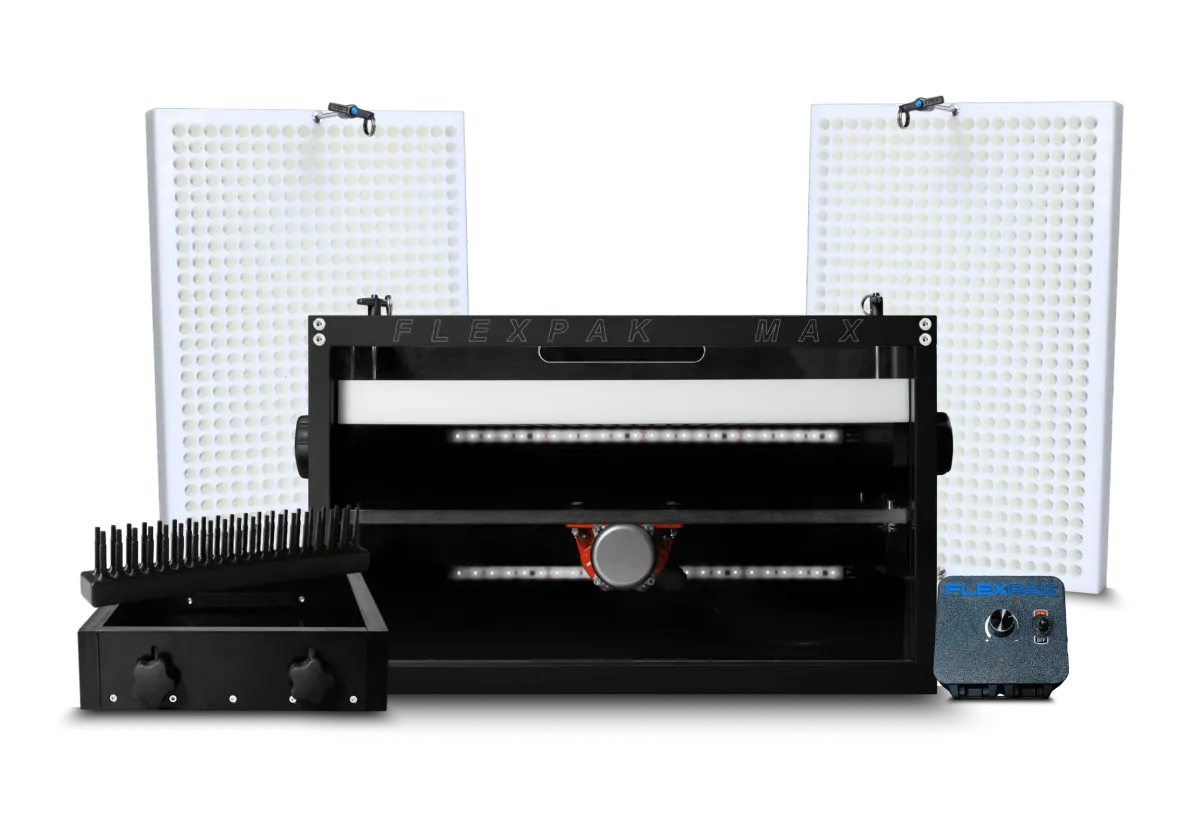

Inside the FlexPak Max: Built Different

Adaptable.

Outsmart Variables. Eliminate Guesswork.

Proprietary Flex Metering™

Real-time metering adjusts to humidity, material, and output demands instantly.

Reduce labor costs by 50% with automated precision that keeps your margins intact.

One customer increased their profit by 28% just by not having to re-weigh joints before packaging.

Reliable.

Machined in Oklahoma, Built for Battle.

No 3D Print. No Cheap Plastic. No Gimmicks.

Full stainless steel and aluminum construction vs. competitors’ 3D-printed parts.

Fully disassembles in <10 minutes for cleaning or repairs. No tech needed.

Consistent durability testing 17K cones/day stress test: 0 failures over 90 days.

Scalable.

From Garage to Global—One Machine, Any Volume.

Production Flexibility.

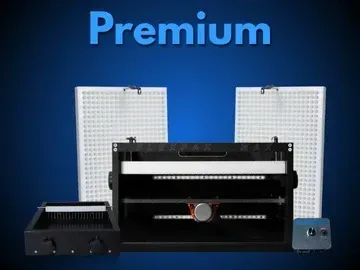

Premium Package: Up to 16,416+ cones/day (1-2 operators).

Pro Package: Up to 24,624+ cones/day (2-3 operators).

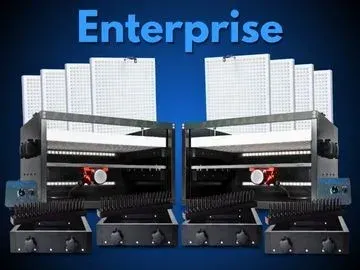

Enterprise Package: Up to 49,248+ cones/day (4-6 operators).

Easily scale up production without breaking the bank by adding a few components at maximum cost-efficiency.

Your ROI Machine:

Start Profiting from Day One with the FlexPak Max.

Your ROI Machine:

Start Profiting from Day One with the FlexPak Max.

FlexPak Max Package ROI Calculator

This calculator provides estimates based on the inputs selected. Actual results may vary.

TESTIMONIALS

What Our Clients Have to Say

"We were reluctant to try yet another preroll machine; however, we pulled the trigger and got a FlexPak Max and couldn’t be happier. We have multiple old machines, many of which were several times more expensive, sitting on the floor collecting dust. The FlexPak machine increased our output by over 3x and they come out ready to go every time. We plan on buying a few more and all the new attachments that are coming soon. Keep up the good work guys!"

Area 52 Farms

“We spent over $50k on pre roll machines that did not operate or perform as promised. The FlexPak Max has replaced them and we are buying a second unit to meet our demand of 100k cones per week!

Ox Distribution

"As the operator of a craft cannabis company in the most competitive market on the planet, I can say with zero hesitation that the FlexPak is hands down the best value for the dollar on the market today when it comes to cones / preroll machines. I currently own and have owned all the other “competitors” machines. It is not even close. Having the ability to scale the machine to meet our needs and the constant innovation from FlexPak, I can see us using the Flexpak exclusively in the near future."

Premium Agriculture

Got 10 Minutes?

See the FlexPak Max Crush 513 Cones in 10 Minutes on a Live Stream Demo.

Forget the Pitch See the Proof.

FlexPak Max

Features & Benefits

That Redefine Pre-Roll Production

Built Different

Features

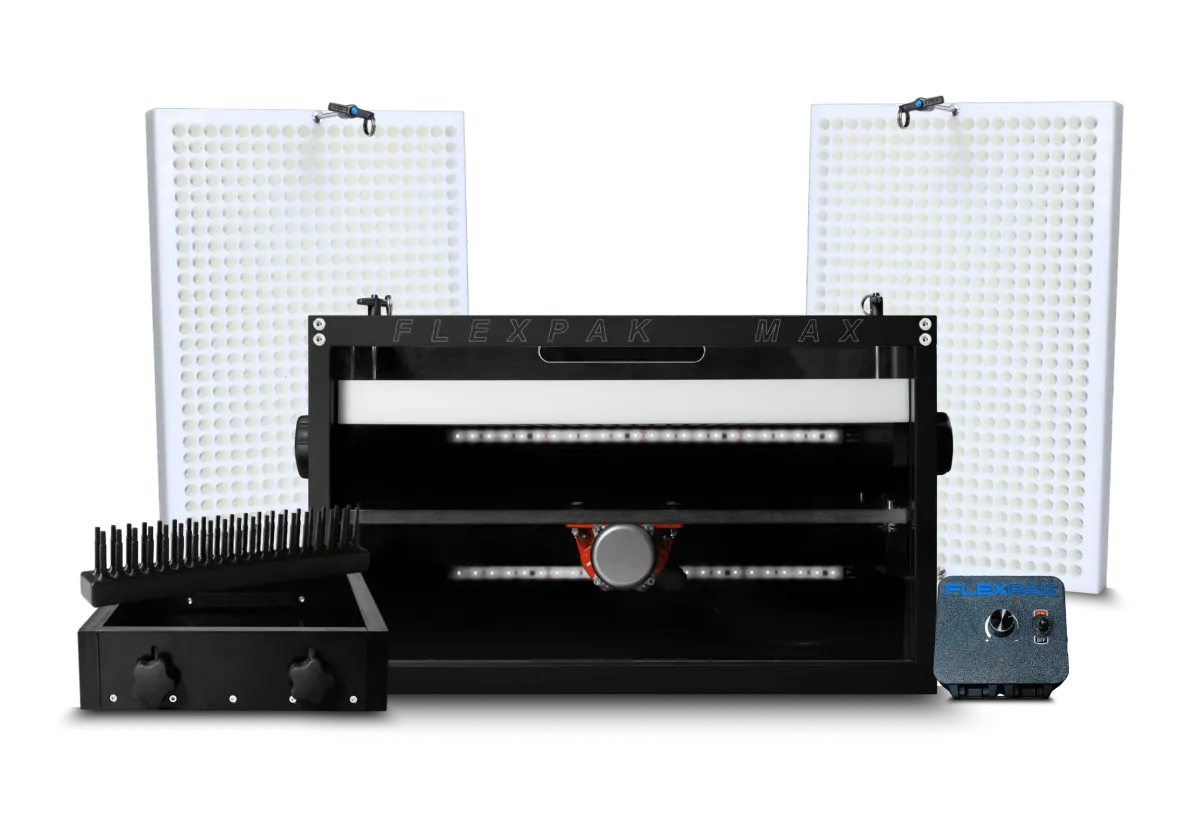

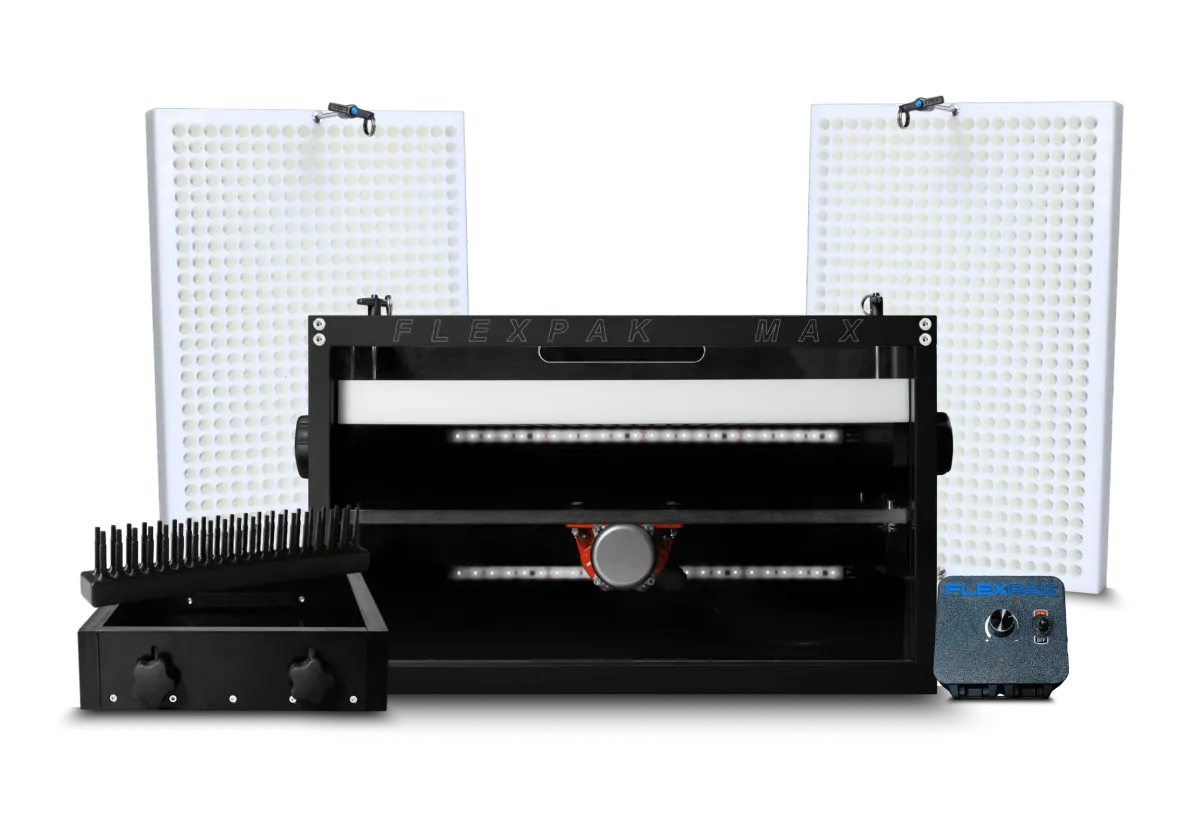

FlexPak Max Machine Core

This machine doesn’t mess around. Every machine is built in our Oklahoma facility utilizing the highest grade locally sourced materials. Made from aircraft-grade T-6 aluminum with a badass black anodized finish, it’s tough, sleek, and ready to work. Stainless steel springs and hardware mean rock-solid reliability, while Lexan vibration plates keep performance smooth and dialed in. And with two high-powered LED strip lights lighting up the interior, you’ll see everything clearly—because precision shouldn’t be a guessing game.

Machine Dimensions:

20 3/4"L x 15" W x 12.5" H

Weight w/ Motor:

60 lbs.

Industrial Strength Motor

This rugged 120V 3-phase industrial vibrating motor packs 50 watts of consistent, hard-hitting power—engineered specifically for high-demand pre-roll production. Built for the long haul, it delivers steady, reliable performance with an impressive 8 to 10-year lifespan. Whether you're running nonstop batches or scaling up operations, this motor is the muscle your machine needs to keep output smooth and efficient without missing a beat.

FlexPak Max Cone Plates

FlexPak cone plates are precision-machined right in our Oklahoma facility using tough, food-grade HDPE. Every plate is tapered to perfection to pack exactly 513 cones with speed and consistency. Engineered to be more durable and more precise than anything else on the market—because close enough just isn’t good enough. Available in 70mm, 84mm, 98mm, and 109mm sizes. Need something custom? We’ll make it happen. Each plate weighs in at a rock-solid 7 lbs of pure, production-grade performance.

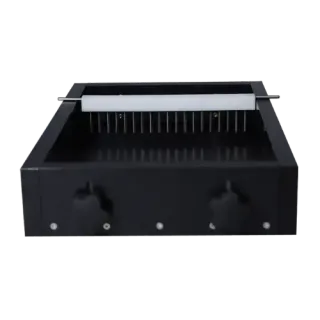

Closing Tool & Set-Up Box

The FlexPak Crowning Tool / Joint Closer is built to speed up your workflow and boost output—no more slow, messy finishes. Pair it with our rugged Setup Box, crafted from food-grade HDPE and reinforced with steel, and you've got a rock-solid prep station that makes cone setup quick, clean, and consistent. Built to take a beating and keep your production dialed in.

Motor Controller

Total Control. Perfect Pack. Precision packing starts with precision power. Our industrial-grade Motor Controller delivers a smooth 120V input with a 120V 3-phase output—built to drive the vibrating motor with exact control. Dial in the speed and intensity to maximize efficiency and pack cones to absolute perfection. Engineered for serious output and long-term reliability, this controller keeps your production locked in and fully optimized.

Benefits

Engineered for 10+ Year Lifespan

Engineered for 10+ Years of Heavy-Duty Production. The FlexPak MAX is built to go the distance. By using high-grade materials—aircraft-quality T-6 aluminum, stainless steel hardware, and Lexan vibration plates—this machine is designed to be your go-to production partner for years to come. Powered by a precision motor controller and lit by dual LED strips, it delivers consistent, efficient performance, day in and day out.

Open Design Build - Easy Clean & Maintenance

Unlike the over-complicated, closed-off designs you’ll find in other machines, the FlexPak MAX was purposely engineered with an open, accessible build. It’s easy to clean, reduces material waste, and simplifies maintenance—because downtime kills productivity. No hidden parts, no unnecessary encapsulation—just smart, efficient design you can fully break down, clean, and rebuild to keep your output consistent and your quality top-tier.

Highest Output. Lowest Cost

The FLEXPAK 513 MAX delivers more filled and closed cones per dollar than any machine on the market. With unmatched volume output, low maintenance requirements, and smooth, streamlined operation, it’s built to crush production goals and slash overhead. More cones. Less time. Bigger margins. If you're serious about scaling, this is the machine that makes it happen.

Flex Metering – Precision You Can Dial In

Forget old-school trays—our Flex Metering system gives you real-time control to adapt to different grades, grinds, and strains on the fly. Adjustable upper rails let you fine-tune cone plate fill levels with surgical precision, helping you hit your target weights every time. More control. Less waste. Consistently better fills. That’s the FlexPak difference.

Assembly Line Workflow & Dedicated Support

We Don’t Just Build the System—We Hand You the Blueprint. After years in the trenches, we’ve perfected an assembly line workflow that maximizes output and minimizes bottlenecks. From cone loading to closing, every step of the process is dialed in for efficiency—and we pass that exact system on to you. But we don’t stop there. Our dedicated support team has seen it all and solved it all. Whether it’s troubleshooting, process optimization, or dialing in your daily ops, we’re here with the real answers—not just tech support, but pre-roll pros with hands-on experience. Efficient systems. Expert support. No guesswork. Just results.

Testimonials

What Others Are Saying

"We highly recommend this machine!"

"Overall this machine has been wonderful to use and it's very user friendly. And no matter what we throw at it it's going to get the job done. And customer support has been on top of everything." - Mary S.

"We do 10,000 a day with two people"

"We run the Max, and with two people we can run abround 10K pre-rolls per day. We tried multiple machines over the years and nothing compares to this one." - Tiana

Why Pay More For Less?

VS

Futurola Knockbox 500 &

STM Rocketbox 2.0

| FEATURES | FLEXPAK MAX |

FUTUROLA KNOCKBOX 500 |

STM ROCKETBOX 2.0 |

|---|---|---|---|

| Pricing | $14,350.00 | $24,998.75 | $24,950.00 |

| Cone Capacity | 513 CONES | 500 CONES | 453 CONES |

| Set-Up Box | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Cone Loader & Unloader | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Joint Closing Tool | ✓ | ✗ Additional Cost | ✗ Additional Cost |

| Lift Plate / Metering Adjustment | ✓ | ✗ Additional Cost | ✓ |

| Maintenance / No Tech Needed | ✓ | ✗ | ✗ |

| Manufactured in USA | ✓ | ✗ | ✓ |

Packages

Choose a Package

That Suits Your Needs

Up to 16,416 Pre-Rolls Per Day

Premium

FlexPak Max Machine

(2) Cone Plates of your Choice

(1) Setup Box

(1) Standard Crowning Tool

Assembly Line Blueprint / Proven SOP's

Lifetime Support / Troubleshooting

MOST POPULAR

Up to 24,624 Pre-Rolls Per Day

Pro

FlexPak Max Machine

(4) Cone Plates of your Choice

(2) Setup Boxes

(2) Standard Crowning Tools

Assembly Line Blueprint / Proven SOP's

Lifetime Support / Troubleshooting

Up to 49,248 Pre-Rolls Per Day

Enterprise

(2) FlexPak Max Machine

(8) Cone Plates of your Choice

(4) Setup Boxes

(4) Standard Crowning Tools

Assembly Line Blueprint / Proven SOP's

Lifetime Support / Troubleshooting

FlexPak Black Glove Set-Up

FlexPak Production Team

Onsite Set-Up & Manufacturing Consultation

Comprehensive Onsite Staff Training

FlexPak Team Does Full Production Run With Staff

* Limited Add-On Package - Contact For Details

FlexPak Senior Team

Zach Sparks

An entrepreneur with over a decade of experience in launching and scaling businesses, specializing in strategic growth and business development across multiple industries.

Director of Sales

Dennis Thompson Jr.

Previous Experience:

- Field Service Technician for Toyoda Machinery Worldwide (TMW)

- Industrial Mechanic 15 years

FEMCO Machinery USA

Operations Manager

Dennis Thompson Sr.

Previous Experience:

- Electrical electronics engineer

40 plus years in the field of engineering and consulting

- Yamazaki Machinery

Toyoda Machinery Worldwide (TMW)

Senior Engineer

Frequently Asked Questions

Your Questions, Answered Clearly

How does your price compare to other machines in the market?

The FlexPak Max cone-filling machine and crowning (joint closing) process is so well priced that the machine will pay for itself within the first 30 days of use, if not sooner. To get an equivalent setup (packing machine and crowning setup) from the closest competitor you’d have to pay $50k-$55k.

What differentiates FlexPak from other Pre-Roll Machine Companies?

Flexpak Inc. was formed by a group of manufacturers that designed a machine to fit their business, through that we’ve solved problems that other machines haven’t, and have produced a machine that does what it is designed to do plus more.

Any type of warranty?

We offer a bumper to bumper One (1) year warranty on the FlexPak Max, we also maintain stock of any wearable items that are easily and cheaply replaced when needed.

Customer Service?

Customer service in this industry, especially on the machinery side is lackluster at best. How we keep our customers happy after purchasing is we have a team designated for zoom demos, questions, tips, pointers, etc. We even offer a lot of information about different areas of the pre-roll process that can also help ensure you're getting the best results possible. There are a ton of factors that go into making a quality pre-roll other than the machinery working as it should.

How much volume can we expect out of the machine?

We usually take a consultative approach and work with you in depth to make sure you get what you need out of your particular setup. We offer three main packages: Premium Package: Up to 16,416+ cones/day (1-2 operators), Pro Package: Up to 24,624+ cones/day (2-3 operators) and the Enterprise Package: Up to 49,248+ cones/day (4-6 operators).

How easily will my team learn this process coming from using different machinery?

The FlexPak Max was designed specifically for efficiency and simplicity. We have customers that come from all different backgrounds and machinery that implement this process smoothly and quickly.

How fast can I receive my setup?

We manufacture these 100% at our facility in Oklahoma, we maintain a good stock of inventory and usually ship within 48 hours of purchase. This however, can vary depending on the order quantity and specifics.

Pre-demo call & consult

Is the Max Right for You?!

Not sure if it’s the perfect fit? Let's discuss your pain points, ask questions, and get tailored insights on the FlexPak Max.

No sales pitch—just solutions.

Book your pre-demo call & consult today!